Professtional Ceramic Wash Basin Factory From China

한유 ceramic wash basin factory established in 2002, and started to supplying 도매 세면대 to companies around the world. Our wholesale and custom bathroom sink products stand out for their outstanding design, premium material quality, and practical functions.

As a wash basin factory that keeps pace with the times, we always improve our production capacity and present better quality to our customers.

Drawing on our extensive experience as a factory, we excel in designing and creating bespoke, innovative, and competitive vanity sink products.

Our Manufacturing Capability

As a forward-looking wash basin factory, We take pride in manufacturing top-quality wholesale ceramic sinks for bathrooms with our superior resources.

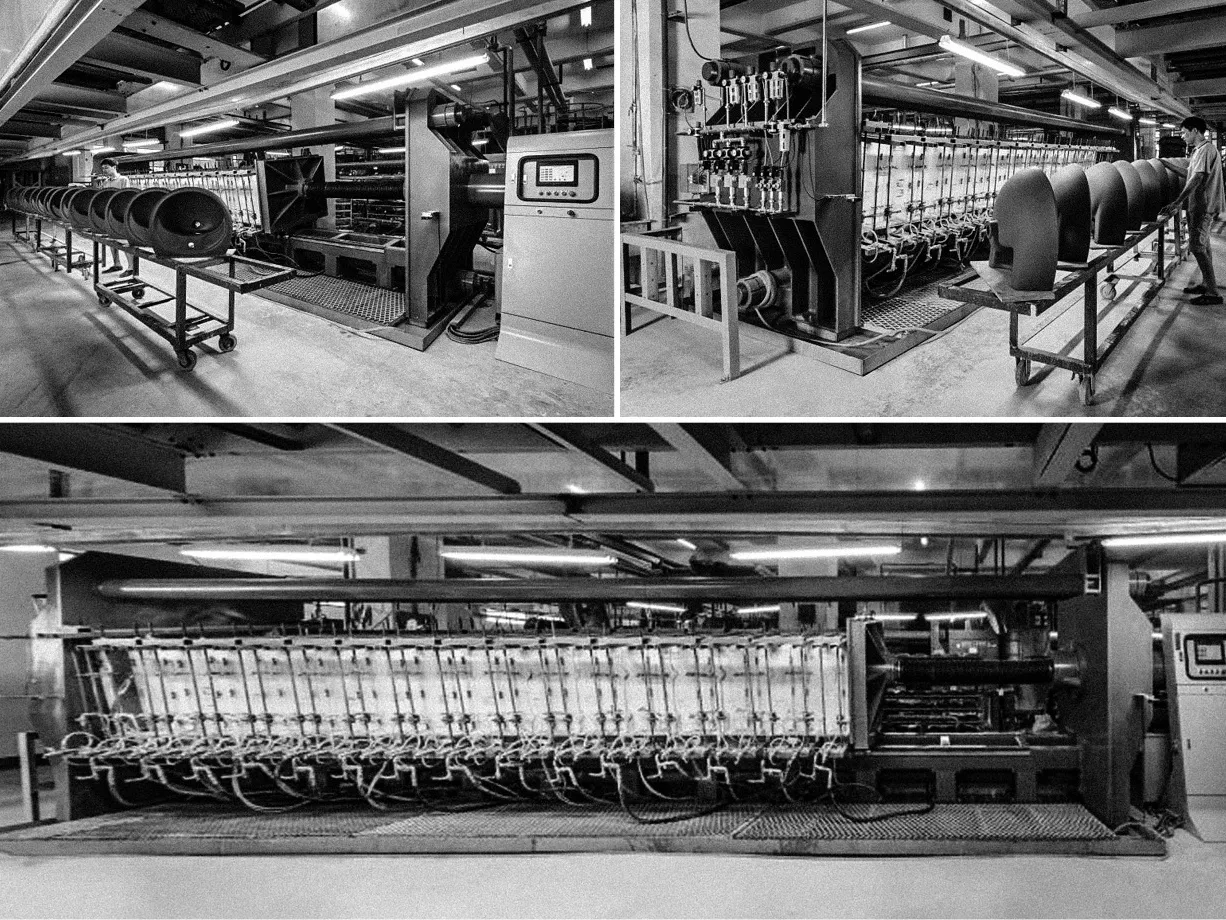

Our Advanced Ceramic Basin Production Line

Hanyu wash basin factory introduced a high-pressure production line in 2015, which often called high-pressure grouting or high-pressure casting. Compared with traditional manual molding and low-pressure molding, high-pressure grouting can significantly improve production efficiency and shorten molding time.

In addition, high-pressure grouting can more accurately control the size and shape of products, reduce errors, and improve product consistency and quality. Due to the uniform pressure during the molding process, the density and structure of the product are more uniform, making it less likely to deform and crack during the drying and firing processes.

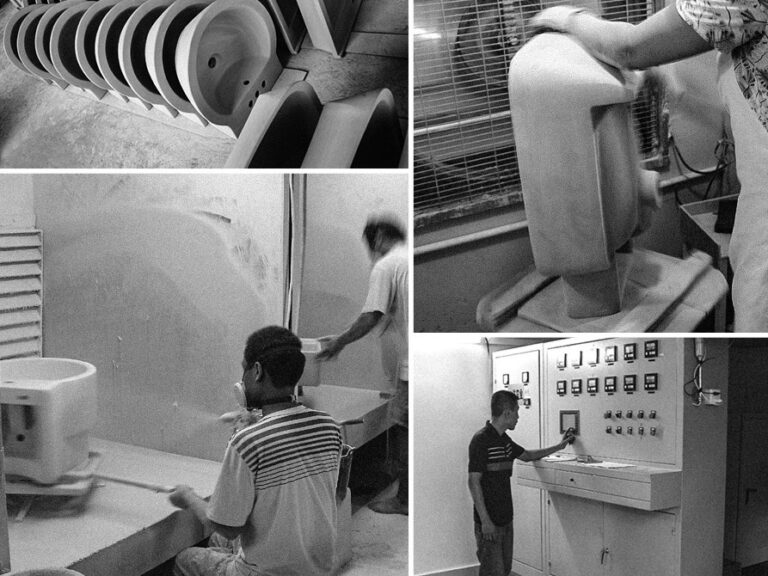

Our Ceramic Wash Basins Manufacturing Process

Take a first-hand look at HanYu ceramic wash basin factory, and explore how we create quality wholesale bathroom sinks in our wash basin factory, from the raw material processing to firing the completed products.

Raw Material

Select high-quality ceramic raw materials, mix them evenly according to the formula ratio, and prepare them into slurry.

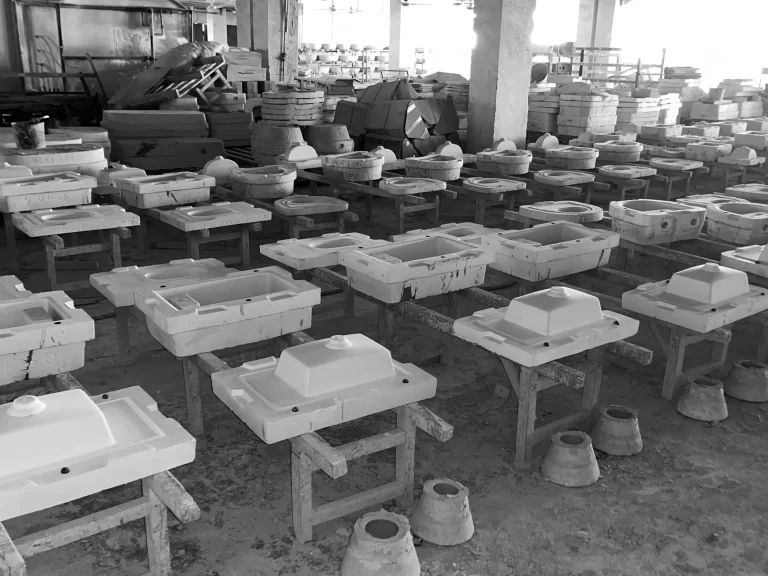

Casting

Inject the ceramic slurry into the mold, distribute the slurry evenly, and let it stand to harden the ceramic body.

Demolding

Remove the solidified body from the mold and check for cracks or other appearance problems.

Fettling

Trim, grind and repair the ceramic basin body to ensure that its surface is smooth and flat.

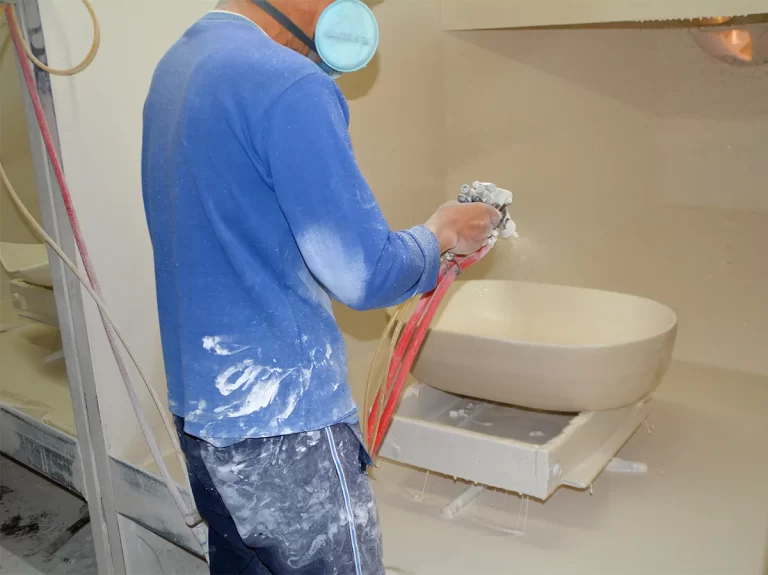

Glazing

Apply glaze evenly to the surface of the body by spraying, dipping or brushing.

Firing

Precisely control the temperature and heating rate to ensure that the glaze is fully melted and combined with the body to form a solid glaze.

Quality Inspection

Perform a comprehensive inspection of ceramic basins to ensure that there are no cracks, defects or other quality problems.

포장

Use shock-proof and drop-proof packaging materials to ensure safety during transportation.

Strictly Select Materials

We deeply know that a premium product starts with a high standard of raw materials. Therefore, we carefully select the best ceramic raw materials on the market. Each batch of raw materials is strictly tested to ensure its purity, which guarantees the excellent quality and durability of our wholesale bathroom sinks.

Serious on Quality Control

Our quality control runs through the entire production process, from raw materials to finished products, each link has a strict quality inspection procedure. HanYu’s professional quality team ensures that every ceramic basin meets the high standard requirements and ensures that every product received by customers is perfect.

Professional Production Management

HanYu’s experienced production management team ensures efficient production and stable quality of products. Our wash basin factory adopts modern production technology and equipment, and strictly follows standardized production process. Continuously optimize the production process, improve production efficiency, and meet the needs of large-scale production.

Fast Order Delivery

We understand the importance of on-time delivery to our customers. We have optimized our supply chain and production processes to ensure that every order can be processed and produced quickly. Strong logistics and flexible delivery methods ensure that products can be delivered to customers in a timely manner.

FAQ About HanYu Ceramic Wash Basin Fartory

We are a manufacturer specializing in the production of high-quality ceramic bathroom sinks. Our ceramic wash basin factory is equipped with advanced production facilities, and we have a professional team dedicated to ensuring the best quality products.

We have a comprehensive quality control system in place. From selecting raw materials to the final inspection of finished products, every step undergoes rigorous quality checks. Our wash basin fatcory use advanced testing equipment and procedures to ensure that our ceramic sinks meet the highest quality standards.

For standard products, the lead time is usually 2-4 weeks after order confirmation. For custom bathroom sink products, the lead time may vary depending on the complexity of the design and other factors. We will provide an estimated delivery time upon order confirmation.

Yes, we can provide samples for you to inspect the quality and design of our products. Sample costs and shipping fees will be borne by the customer, but the sample cost can be refunded upon placing a bulk order.

Our ceramic wash basin factory is located in Chaozhou, Guangdong Province, China. It is equipped with state-of-the-art machinery and staffed by skilled workers dedicated to producing top quality ceramic bathroom sinks.

Sure, we highly welcome visitors! HanYu ceramic wash basin factory has 10 rolling production machines, 10 single high-pressure production machines, 2 high-pressure casting production lines, 28 production lines, 2,000 production molds, and 2 advanced computer-controlled kilns.

Please contact us in advance to schedule an appointment. We would be delighted to show you our production process and facilities, and answer any questions you may have about our products or manufacturing process.